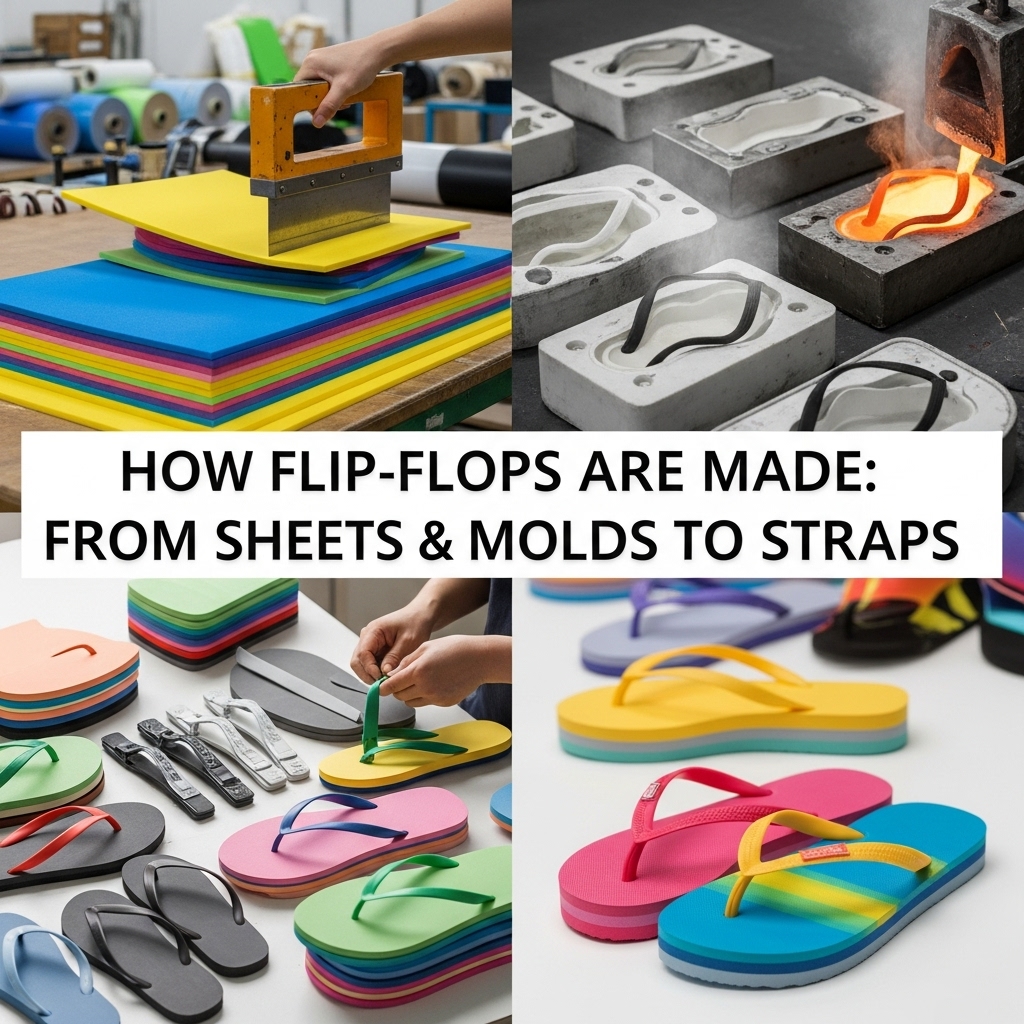

How Flip-Flops Are Made: From Sheets & Molds to Straps

Flip-flops are some of the world’s simplest-looking shoes—but behind their lightweight feel and warm-weather comfort lies a surprisingly technical manufacturing process. Every strap, footbed contour, and outsole detail is engineered to support the foot, withstand heat, resist water, and stay comfortable through long days outdoors.

Using the same principles found in fit and strap-style guides—secure toe-post placement, supportive footbeds, durable rubber compounds, and precise molding—this article breaks down exactly how flip-flops are made, from base materials to finished pairs ready for the beach.

1. Choosing the Right Base Materials

Before any cutting or molding begins, manufacturers choose materials based on durability, comfort, weight, and intended use. High-quality flip-flops use heat-resistant, flexible, and water-friendly compounds.

Common Footbed & Sole Materials

- EVA (Ethylene Vinyl Acetate): Lightweight, cushioned, shock-absorbing—perfect for all-day comfort.

- Rubber: Durable, heat-stable, slip-resistant, and ideal for beach and pool surfaces.

- Blended foams: Offer softness while maintaining structure under heat and pressure.

The chosen material determines how the flip-flop will behave during wear—whether it will support the arch, maintain comfort in heatwaves, or resist water and sand.

2. Creating EVA or Rubber Sheets

Many flip-flops start as large sheets of EVA or rubber foam. These sheets are produced in presses or extrusion machines that expand the material with air, giving it cushioning and flexibility.

Steps include:

- Mixing raw EVA pellets or rubber compounds with coloring agents.

- Expanding the material under heat and pressure.

- Cooling to stabilize the foam’s density and thickness.

- Cutting into uniform sheets for further shaping.

Some brands use multi-layer sheets to combine contrasting colors, add heel support, or improve overall durability.

3. Cutting the Footbed Shape

Once the sheets are ready, they’re cut into the familiar flip-flop silhouette. Manufacturers use cutting dies—metal shapes pressed into the sheet, much like cookie cutters—to punch out the footbed.

Why this step matters:

- It defines the base size and shape.

- It determines toe spacing and heel width.

- It ensures uniformity across batches for consistent fit.

Brands known for comfort refine the width, toe area, and arch shape based on ergonomic data and customer testing.

4. Injection Molding (For Molded Flip-Flops)

Many flip-flops—especially those with contoured footbeds—use injection molding instead of sheet cutting. This method allows for finer details, such as arch support, heel cups, and textured surfaces.

How Injection Molding Works

- Raw EVA or rubber is melted into a liquid state.

- The material is injected into steel molds shaped like left and right footbeds.

- Pressure ensures the material fills every contour.

- The mold cools, solidifying the shape.

- The footbeds are removed and trimmed for finish.

This process is essential for flip-flops that focus on support, posture, and all-day comfort.

5. Adding Texture & Grip to the Footbed

Slip resistance isn’t just for the outsole—footbeds need grip too, especially when feet get wet or sweaty in warm climates.

Surface textures help:

- prevent slipping inside the flip-flop,

- keep the foot centered around the toe-post,

- increase comfort during long wear,

- and allow airflow under the sole.

Patterns include ridges, dots, waves, and geometric designs depending on the brand’s aesthetic and functional goals.

6. Designing and Manufacturing the Straps

Straps are the heart of flip-flop comfort. The reference emphasizes how strap style—toe-post, fabric-thong, or slide—determines stability and long-term wearability.

Toe-Post Straps (Thong Straps)

- Made from rubber, EVA, or soft plastics.

- Molded into a Y-shape that anchors between the toes and along the sides.

- Often reinforced at the center post for durability.

Fabric Thong Straps

- Usually stitched using cotton, recycled polyester, or nylon webbing.

- Padded for softness and to reduce friction.

- Ideal for comfort-focused or travel-ready models.

Slide Straps

- Wide, single-band designs.

- Made from synthetic leather, rubber blends, or fabric overlays.

- Provide stability and a snug fit when properly structured.

Each strap style interacts differently with the foot, influencing comfort, toe grip, and support.

7. Attaching Straps to the Footbed

Attachment is crucial—poor anchoring leads to broken straps and unstable footing. Manufacturers use one of two main methods:

1. Plug-In Anchoring

The most common method. The end of each strap has a small mushroom-shaped plug that pushes through a hole in the footbed. When pulled tight, the plug locks beneath the sole.

Advantages:

- flexible movement,

- easy manufacturing,

- strong hold against pulling and twisting.

2. Molded-In Straps

Used for single-mold flip-flops or waterproof styles. The strap and footbed are molded together in one piece, offering maximum durability and water resistance.

8. Outsole Patterning for Traction

Whether cut from sheets or molded, the outsole receives traction patterns designed for specific environments—beaches, pools, slippery tiles, or general outdoor use.

Common tread styles:

- Wave patterns for wet surfaces

- Chevron or herringbone for street grip

- Multi-directional lines for natural movement

High-quality outsoles prevent slipping and improve stability, especially in hot or wet climates.

9. Printing, Finishing & Branding

Before packaging, flip-flops receive aesthetic touches:

- Printed graphics on the footbed

- Brand logos on the straps or outsole

- Heat-transfer artwork

- UV-resistant coatings to prevent fading

These finishing steps highlight the brand identity and protect the product from sun damage—a major factor for beach footwear.

10. Quality Control

Every pair undergoes testing to ensure comfort, safety, and durability. Quality checks include:

- strap pull strength,

- flexibility of the footbed,

- outsole traction testing,

- color resistance under heat,

- stitching and bonding inspections (for fabric straps).

Only after passing these checks do flip-flops move on to packaging.

Final Thoughts

Though simple on the surface, flip-flops involve a precise blend of material science, ergonomic shaping, strap engineering, and careful molding. Each step—from sheet cutting to injection molding to strap anchoring—affects comfort, durability, and the overall experience of wearing the pair.

Understanding how flip-flops are made helps you appreciate why strap style, footbed support, and outsole traction matter so much. With thoughtful construction, a pair of flip-flops becomes more than casual footwear—it becomes a reliable, comfortable companion for warm-weather living.